The Cox & Plant Way

My aim is deliver value to our customers and drive their revenue by becoming a trusted partner. Our projects always deliver against exacting global standards which offer the most robust justification of why investment in our technology and manufacturing excellence, is safe and trusted.

My team will comprehensively handle your project needs from concept through to installation. Our engineering design team will study and analyse your current processing infrastructure, evaluate your needs, and specify the product mix required to meet your project goals.

Our turnkey solutions are notably different for each client – whether it is a family business or a multinational. Our mission is to understand your business, then tailor and deliver the precise solution that will maximise your return on investment.

We are open, honest and totally committed to exceeding your expectations, allowing you to compete in an ever-changing marketplace, expand your reach and accelerate your business growth, improve profitability and revenue.

Andrew Cox

Managing Director

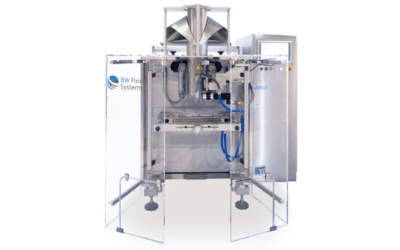

Distribution Systems

The Background:

Distribution systems and cross head feeders (CHF) are usually an afterthought, however, ROI can be achieved in as little as 6 weeks. The conveying equipment and the feed to the CCW multihead is critical for accurate weighments and minimum product giveaway. We can also address line priority resulting in zero downtime or starvation of product.

The Challenge:

The biggest challenge of a distribution system to ensure that there is no line starvation and all individual branches are consistently and constantly fed. This will ensure that all baggers and CCWs are running at optimum efficiency and productivity. Options include on the head flavouring for more bespoke specialist facilities where each individual line would require its own unique

Our Solution:

The line methodology logic from a design concept is similar to effective traffic management on a smart motorway. Product flows through the main line distribution conveyors where each of the “junctions” can be called from the CCW multihead weigher to deliver product. This ensures no starvation and all the multihead’s are replenished on demand with ready to pack product.

Customised options include pneumatic gate options (sliding, pivot and quadrant) where product falls below onto the CHF. For lighter products such as cereals or snacks our gateless flow management system is ideal when height is a restrictive factor.

The Results:

After 5 decades in business our systems are tried and proven throughout the world, we always recommend accumulation / buffer storage to act as a reservoir to ensure the line is primed with product and accommodates the voids and surges in batch processing. Our systems are supplied with PLC controlled HMI panels with security levels of entry to ensure not only do you maximise production, metrics and trends can also be analysed shift by shift and hour by hour.