BW Flexible Systems Vertical Form, Fill and Seal (VFFS)

The BW Flexible Systems Vertical Form, Fill and Seal (VFFS) bagging product line features a variety of continuous and intermittent motion bag filling systems. Our vertical bagger systems are capable of filling low, medium and high-speed packaging applications for a variety of products and industries. When you choose a vertical bagging solution from BW Flexible Systems, you receive more than a superior product. Our vertical form fill machines are fully protected by our lifetime service guarantee. We believe that our customers are our partners and are committed to ensuring that your vertical bagger is supported by our local technicians.

VFFS Support

With more than 100 years of experience in the flexible packaging industry, we know that your needs are unique. Our solutions are customized to meet the unique needs of your line. We provide varying speeds, quick change capabilities, and the ability to provide packaging in hundreds of different sizes. Vertical Baggers are able to provide packaging for food, frozen products, household goods, and more. Contact BW Flexible Systems to learn more about how our solutions can be customized to work within your existing infrastructure and increase efficiency.

Overview

KayDee Solutions is a specialist supplier of high quality bag making and packaging machinery from market leader, BW Flexible Systems. BW Flexible Systems Vertical Form/Fill/Seal (VFFS) machinery is ideal for a broad range of packaging applications and the KayDee Solutions team can specify and design the best solution for your requirements. BW Flexible Systems VFFS from KayDee Solutions can produce a wide range of package styles including:

- Pillow bag with or without slide or press to close zipper

- Gusseted tucked bag with or without slide or press to close zipper

- Tucked bottom bag

- Three side seal with or without slide or press to close zipper

- Four side seal with or without slide or press to close zipper

- Flat Bottom Bag with or without slide or press to close zipper

- Quad Seal with or without slide or press to close zipper

- Doy with or without slide or press to close zipper

- Tetrahedron package

- Saddle Bags

All Vertical Form/Fill/Seal packaging systems supplied by KayDee Solutions are designed to maximise performance, reliability and ease of maintenance, features include:

- Continuous or intermittent motion systems

- Flexible systems for changing requirements

- Multi-lingual interfaces

- Wide speed ranges and bag styles

- Synchronisation with printers, labellers, feed systems and metal detection etc

- Optimum utilisation of floor space

- Hygienic easy wash-down designs

- Modular assemblies for quick changeover and reduced setup times

- Resistant to chemical and cleaning products

KayDee solutions can also provide film materials and consumables for your VFFS packaging system for a complete packaging solution.

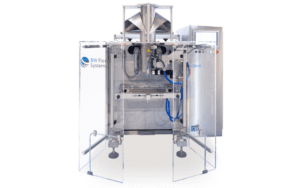

Verus 35/45 VFFS

Verus 35/45

The high operational efficiency of the Verus is achieved by its reliable, functional, and durable design and construction, but also an ease of use, operation, and maintenance. Bag format changeovers are a matter of minutes between simple format sizes. With a multitude of features and options, the Verus bagger is one of the most versatile, efficient, and competitive machines on the market.

Technical Data

Production Rate

- Up to 110 bags per minute (depending on bag style and size)

Package Range

- VERUS 35

- Min. Flat Bag Width: 50 mm

- Max. Flat Bag Width: 320 mm

- VERUS 45

- Min. Flat Bag Width: 70 mm

- Max. Flat Bag Width: 400 mm

Power Requirements

- 380-480 Vac, 3 Ph, 50/60 Hz

Air Requirements

- 5.8 Bar – Clean, dry air

Product Detail

- Robust and sanitary design suitable for a wide range of challenging industries

- High speed intermittent motion with precise film control

- Flexible bagger with a large range of bag styles:Quad, Block Bottom, Gusseted, Pillow, Strip and Resealable Zipper

- Range of sealing systems for polyethylene and/or heatseal materials

- Allen Bradley CompactLogix control system with color 6” touch screen operator interface with choice of languages and access restriction feature

- Stainless steel and aluminum construction with IP65 electrical cabinet and HMI enclosure

- Acrylic or laser-cut stainless steel front guards

- Stepper motor-driven pull belts Servo driven jaw actuation for high speed and high sealing integrity

Download Verus Brochure Verus VFFS