Kronen develop and produce single and special machines as well as complete processing lines for preparing, cutting, washing, drying, peeling and packing of food. Their quality and their consulting competence are appreciated world-wide.

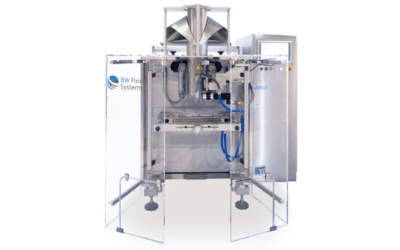

Complete Salad Processing Line up to 800 kg/hr

Complete salad processing line for cutting, washing and drying of leaf salads up to 800 kg/h of following KRONEN-machines:

- Belt cutting machine GS 10-2 or Belt cutting machine GS 20

- Washing machine GEWA 3800V PLUS or Washing machine GEWA 2600V PLUS

- Spin dryer KS-100 PLUS

This salad processing line can be run efficiently with a minimum operating staff. The GS 10-2 – proven in over 1000 applications – combined with the reliable GEWA washing machines provide top performance at an unbeatable price / performance ratio.

Benefits

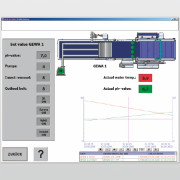

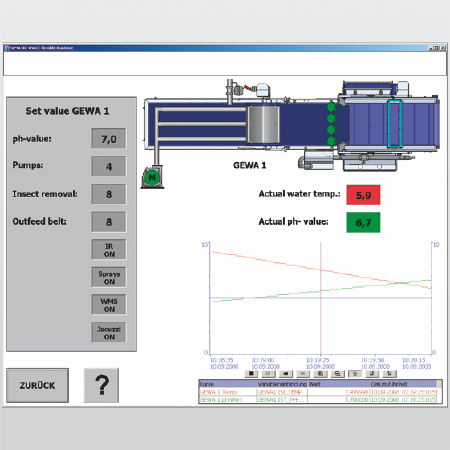

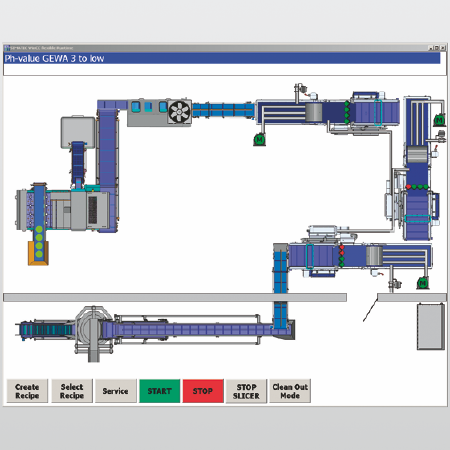

Process automation and visualisation

For complex systems, there is a need to intelligently network them. This is possible with the help of KRONEN’s process visualisation components.

These process visualisation components, in conjunction with the optionally available bus system, allow immediate localisation and response of system messages such as maintenance messages or error messages. For example: In case of a product jam, the system automatically switches off upstream machines, thus preventing the waste of valuable raw products.

In addition, the system can be flexibly controlled by an operator center via touch screen or PC and adapted to the production processes. This facilitates the adaptation of the system performance to different capacities, products or product mixtures.

Optimal adaption of machines

All components of a line of KRONEN machines are adapted optimally in order to tap the full throughput potential of every machine and to maximize the total throughput of the line. Thus, bottlenecks in the production process as well as any overcharge of the machines are avoided. This leads to energy savings as well as reduction of maintenance costs.

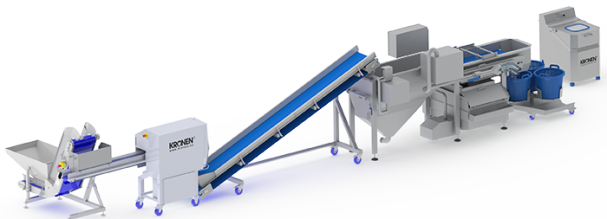

Salad processing line up to 1000 kg per hour

Salad processing line for trimming, cutting, washing and drying of leafy lettuce and vegetable up to 1000 kg per hour

Consisting of following KRONEN machines:

- MULTICORER

- Belt cutting machine GS 10-2 or Belt cutting machine GS 20

- Washing machine GEWA 5000B PLUS

- 2 x Spin dryer K50-100S

Benefits

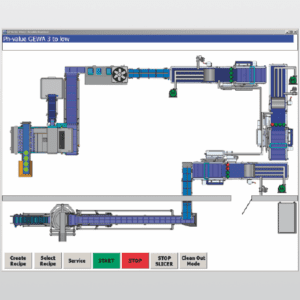

Process automation and visualisation

For complex systems, there is a need to intelligently network them. This is possible with the help of KRONEN’s process visualisation components.

These process visualisation components, in conjunction with the optionally available bus system, allow immediate localisation and response of system messages such as maintenance messages or error messages. For example: In case of a product jam, the system automatically switches off upstream machines, thus preventing the waste of valuable raw products.

In addition, the system can be flexibly controlled by an operator center via touch screen or PC and adapted to the production processes. This facilitates the adaptation of the system performance to different capacities, products or product mixtures.

Optimal adaption of machines

All components of a line of KRONEN machines are adapted optimally in order to tap the full throughput potential of every machine and to maximize the total throughput of the line. Thus, bottlenecks in the production process as well as any overcharge of the machines are avoided. This leads to energy savings as well as reduction of maintenance costs.

GS10-2 Belt Cutter

Worldwide top-selling belt cutting machine for cutting of salad, vegetable, herbs, meat, fish, sausage and grating of bread, cheese and nuts.

The GS10-2 is equipped with a conveyor belt of 125mm width with perfect downholder technique for correct and soft product guiding.

Stepless adjustment of cutting length from 1-50mm.

GS20 Belt Cutter

For industrial cutting of salad, vegetable, fine herbs, fruits and many more products.

The newly developed GS 20 belt cutting machine is equipped with a conveyor belt 250 mm wide with a product down-holder to apply proper pressure for product control. This key feature holds and controls the product until point of cutting.

Individually definable programs can be stored and selected by the simple useof control buttons and features digital in-motion cutting size adjustment from 1 to 50 mm using a knife with 3 blades. The GS 20 feeding belt has been designed to convey whole heads of lettuce or cabbage.

The easy handling joins our series of all established KRONEN GS belt cutting machines. Concerning the product outfeed the knife cover has been optimized, in order to allow a gentle product handling.

The downholder gear and the diversion rollers were further improved and spare parts reduced consistently as far as possible, taken into account an additional improvement of the product quality.

Indicator lights indicate the status of the safety sensors. A new locking system combined with a new belt cover creates additional safety in the area of the knife. As with all KRONEN machines, its excellent hygiene qualities are a major advantage: Inclined surfaces, stainless steel shaft seals and the elimination of screws in the cutting chamber door area, a seamless knife edge, etc. contribute to the improved performance of the GS 20 belt cutting machine.

The solid industrial machine is completely made of stainless steel. It has been conceived caring specially about simple maintenance, easy and efficient cleaning and is, therefore , best suitable for professional applications.

GEWA 3800V PLUS

Washing machine GEWA 3800V PLUS with vibration outfeed (product outfeed over vibration screen)

for medium capacities, for example approx. 200-1000 kg per hour, depending on product.

Efficient and gentle washing of lettuces, vegetables and fruit by means of adjustable water rotation.

Benefits

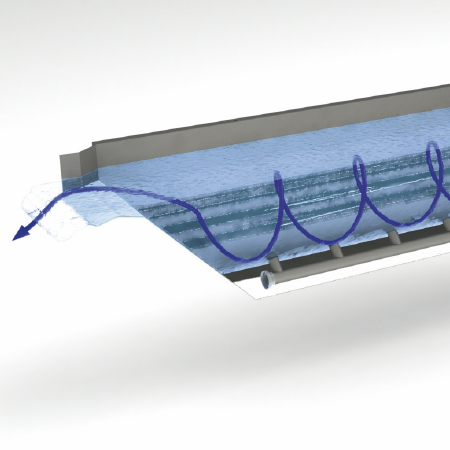

HELICAL wash system

The KRONEN HELICAL washing system permits the product to pass through the washing tank along an adjustable water spiral, which means a distance of approximately four times the length of the wash tank itself.

Compact and modular construction

The GEWA washing machines assembly is modular. This allows our machines to adapt to different production requirements and conditions, for example changing the discharge system from vibration to belt conveyor, or installing a new air bubble system on an existing machine. Mounting new optional devices to existing machines can be done by yourself or by our trained service team.

Sand trap

Heavy dirt particles (like small stones) and sand are removed from the product flow and settled separately in the sand trap, at the bottom of the wash tank. Thus we avoid the sand particles to return to the product flow.

Cleaning and maintenance

All pipes, pump cases, wash and pump tanks as well as covers and control panels are manufactured in AISI 304 stainless steel. Furthermore, KRONEN machines have been designed caring specially about:

- simple maintenance

- easy and efficient cleaning

- low operating costs

Spin-dryer KS-100 PLUS

The KS-100 PLUS, the TOP-seller of KRONEN spin-dryers for vegetables and salads, field-tested and in action hundredfold world-wide, has a new look.

Besides a new design especially the further technological development is on focus.

The robust construction, safety and function are based on the requirements of the centrifuge DIN EN 12547 standard and the salad spin-drying DIN EN 13621 standard.

Benefits

Ergonomic lift-height & 99 memory locations

The ergonomically low lift height together with individual adjustment options for spin speed and duration on 99 freely programmable memory locations ensure maximum comfort and optimal adaptation to the product to be processed. A mode with spinning in both directions during the program is also available. The counter-rotating centrifuge cycle automatically changes the direction of rotation after half a spin period. The product is thus additionally loosened up and dries more efficiently.

Open construction facilitates cleaning

The KS-PLUS spin dryers are particularly easy to clean.

There are no dirt traps in the spin area: no screws are used, a floor slope and a drain pipe with a diameter of 100 mm guarantee optimal water drainage. The lid lock is located in the rear mechanism housing.

The powerful but low-noised motor assures marginal wear and high durability.

Reduction of dripping-off time

The dripping-off times of canned products such as e.g. crabs, tunas, pineapples, mushrooms as well as frozen bell pepper or onion pieces are reduced considerably.

Food safe components

All components that are in contact with food are made of stainless steel or FDA-compliant plastics.

K650 Drying System

The K650 drying system is the ideal system for drying a wide variety of lettuce and vegetable products in a continuous treatment process. The K650 drying system is perfectly suited for drying sliced fruit, vegetables, lettuce, mushrooms and herbs in the industrial application.

Depending on consistency, shape and size of the product and the desired degree of drying, spinning times and spinning speeds can be adjusted via a touch screen and saved in the programs. Depending on the cycle time and rotational speed, some parameters are automated, e.g. speed of the buffer conveyor and of the outfeed conveyor. Thus, the program is clearly organised and easy to operate.

With an optional volume control, the product feed quantity can be optimised. This influences the capacity and the drying effect. In addition, without product the machine switches to energy saving mode automatically.

Production sequence:After the washing process, the product is collected on a buffer conveyor depending on the spinning time, and afterwards it is dried in the centrifuge. According to the product and quantity different programs can be chosen. This enables an effective, gentle and short drying cycle. At the end of the drying cycle the rotational speed is reduced and through one-time blow-off, the product is gently further routed out of the centrifuge and onto an outfeed conveyor.

The outfeed conveyor is cycled in such a manner that a product flow that is as uniform as possible occurs for the downstream processes (including weighing / packing).

The K650 drying system is an ideal supplement to the KRONEN GEWA washing machines and it can be integrated in all other systems that require a continuous, user-friendly drying process operated with a minimum number of personnel.

Benefits

Easy operation via touch screen

In the movable control cabinet there is a touch panel in which the appropriate programs can be quite easily entered, modified and saved.

The important parameters include the spinning speed, the spinning duration, and an optionally adjustable right-hand / left-hand rotation mode for large-leaf products.

Hygiene and cleaning

The K650 is manufactured completely of AISI 304 stainless steel or FDA-conformant plastics (all surfaces that come into contact with food).

For optimal cleaning and hygiene the seal can be mounted and dismounted without tools.

Also for the feed conveyor and buffer conveyor, as well as for the outfeed conveyor the conveyor belts can be quickly and easily taken off through a rapid de-tensioning system. The robust machine has been designed in accordance with the latest hygienic regulations and thus it can be cleaned easily and quickly.

Flexible set-up variants

The supply of the product can occur from two sides and the outfeed can occur in 5 different directions.

Thus, 8 different set-up variants are possible that ensure the greatest possible flexibility depending on the customer requirement.

Cutting and Peeling

HGW cutting machine for manual cutting of fruit, salad, vegetables and other food.

The abrasive peeling machine PL 40K peels and washes potatoes, carrots, beetroots and other root vegetables.