Rosenqvists Food Technologies AB started in 2009 when a group of experts with long experience and background from the development and design of processing lines for the potato processing and snack food industries joined Rosenqvists. The group of people came from PPM AB ( Potato Processing Machinery AB ) ,Kristianstad, Sweden, which for more than 40 years had used the manufacturing expertise of Rosenqvists to build the complete processing lines.

Our goal is to create complete, value-added solutions for the food processing industry. Our focus is on processing lines for French fries and the snack food industry. (complete lines for potato chips and frying systems for pellets, prefabricated chips, peanuts, batch fried chips, tortilla, wet pasta,etc.)

Read More:

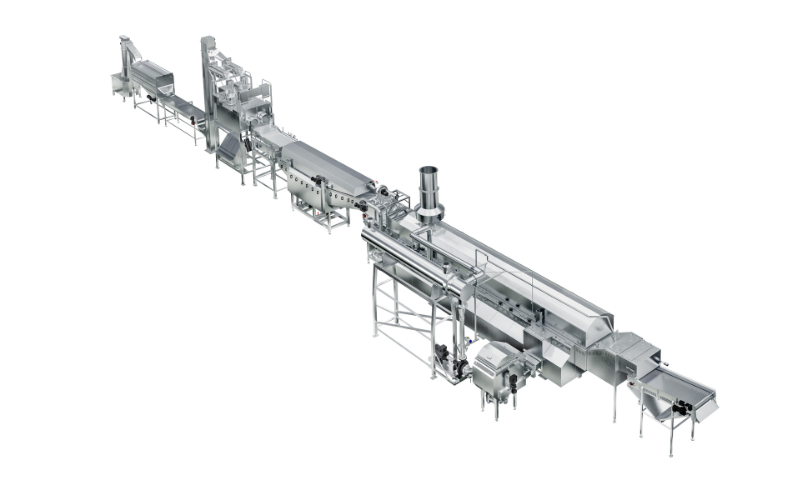

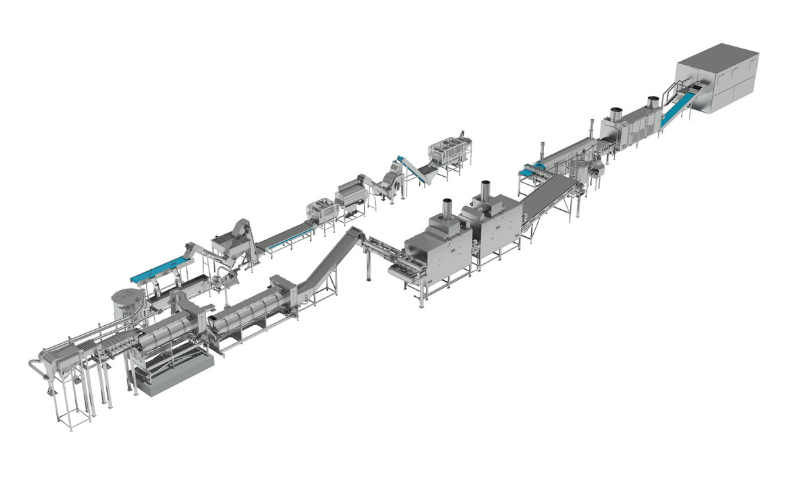

REGULAR CHIPS PROCESSING LINE

DEVELOPING AND DESIGNING POTATO CHIPS LINES FOR MORE THAN 40 YEARS

Developing and designing potato chips lines for more than 40 years Rosenqvists Food Technologies has extensive knowledge of the potato as raw material and how to design an effective process. We combine the latest technologies using computer simulation programs and build efficient and reliable process equipment. We take responsibility for design, manufacture and installation. We will commission the line and make sure that your staff get professional training in maintenance and process control.

STEP 1: PREPARATION

Potatoes are destoned and washed in the Rosenqvists Vertical Screw Destoner. For more difficult soil conditions, we recommend our Cyclone Destoner. The Continuous Abrasive Peeler peels the potatoes gently with an even and accurate result.

STEP 2: SLICE WASHING

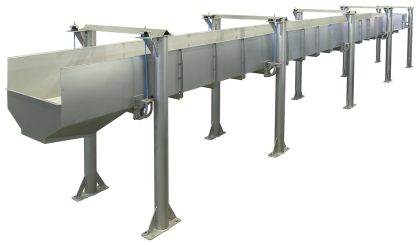

After slicing, the starch on the surface of the slices needs to be washed away.

The Rosenqvists Slice Washer uses minimum amount of water to gently clean the potato slices. Small potato particles are effectively removed from the product flow.

STEP 3: BLANCHING

If your raw material contains higher levels of sugar, the blancher will leak out/reduce the sugar level so that a golden chip can still be produced. The unique Zone Blancher separates every single slice for optimum and even blanching result. The temperature, set in three zones and the paddle belt assure a controlled and exact blanching effect. The bottom belt design allows to run the blancher without water when processing chips of low-sugar level potatoes.

STEP 4: MULTI-ZONE FRYING

The critical phase in the potato chip process is the frying phase. With controlled oil flows and Multi-Zone design, the Rosenqvists frying system will be frying the potato slices to perfect texture, bite and colour. Low total oil volume, special design hood, etc. guarantees the best final product quality.

SUPERIOR FRYING WITH STAR WHEEL FRYER

EFFICIENT OIL MANAGEMENT

- Lowest oil volume of any pellet fryer on market

- Quick oil turnover rates—just 2-4 hours

OPTIMUM PRODUCT QUALITY

- Adjustable frying time from 8-50 seconds

- Precise, controlled frying time due to frying wheel

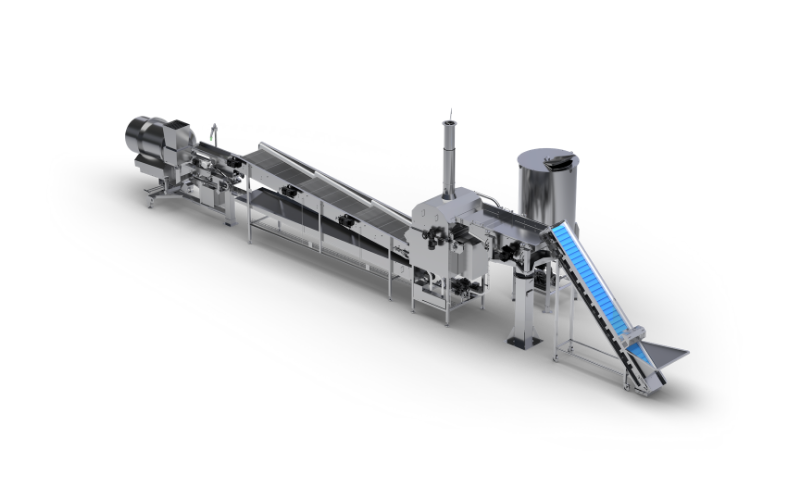

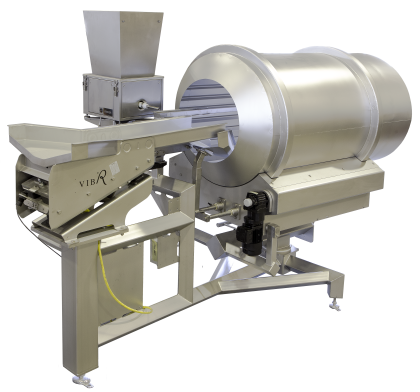

UNIQUE PELLET FRYING SOLUTION

The patented Star Wheel Fryer (SWF) provides gentle handling and uniform frying of many different pellet snacks from rings to 3-dimensional products. With the lowest total oil volume of any pellet fryer on the market, the patented Star Wheel fryer is available in three sizes with outputs from 100-750 kg/h.

PERFORMANCE

The SWF system has very low total oil volume with the smallest model containing only 140 liters for a capacity of up to 150 kg/h. The low oil volume equates to exceptional turnover rates at just 2-4 hours optimizing product quality and extending shelf-life. And, for added convenience, the oil level of the fryer is automatically controlled.

OPERATION

The SWF system is designed to give you maximum flexibility in the production of top-quality snacks. From rings to more complex 3-dimensional snacks, the SWF easily and efficiently handles a wide variety of pellet products.

With adjustable frying time from 8-50 seconds the patented and state of the art frying wheel design, the pellets will be uniformly fried.

An advanced controller maintains and controls oil temperature.

The infeed system consists of an incline elevator to handle the most fragile of products and a vibratory conveyor with built in screen to remove small pieces. After the fryer the fried product passes an oil-drip-off belt prior to the seasoning process.

The installation is simple with pre-assembly of all pipes between oil supply tank, level control and fryer.

The SWF system is designed with easy operation and CIP cleaning.

The exhaust stack is removed allowing easy access to the frying wheel which is lifted via a motor-driven lifting system.

FRYING FRENCH FRIES

DEVELOPING AND DESIGNING FRENCH FRY LINES FOR MORE THAN 40 YEARS

Rosenqvists Food Technologies has extensive knowledge of the potato as raw material and how to design an effective process. We combine the latest technologies using computer simulation programs and build efficient and reliable process equipment.

We take full responsibility for design, manufacture and installation. We will commission the line and make sure that your staff get professional training in process control and maintenance.

STEP 1: PREPARATION

As potatoes are received, they are sorted and pre-graded to correspond with the type of French fry to be produced. Potatoes then enter the line and pass through the destoner and washing process before being peeled.

STEP 2: STEAM PEELING AND INSPECTION

After steam peeling the de-skinner removes and collects the peel waste. The potatoes are then washed clean prior to being inspected and transported to the cutting process.

STEP 3: CUTTING

The cutting process is performed by either a hydro-cutting or mechanical cutting system. These machines cut the potato into strips – crinkled or straight to the desired size, then the strips pass through the equipment that removes slivers and nubbins.

STEP 4: BLANCHING

The potato strips pass through a blanching system, consisting of two or more screw blanchers. Here the strips are gelatinized and the sugar levels reduced, then they go through the SAPP—dipping belt before being pre-dried.

STEP 5: DRYING

During the drying process (which is optional for smaller lines) the moisture content is reduced and the strips are now ready for the frying process where the final texture and colour are achieved. Before entering the fryer the French Fries are transported on the Equilibration belt to get an even moisture content.

STEP 6: MULTI ZONE FRYING

With controlled oil flows together with Multi-Zone design and the belt-return outside of the fryer pan Rosenqvists frying system will give you the best tools to achieve the desired texture and colour. After frying the French fries will pass a de-fatting step. For coated fries and other potato products, a batter and pre-frying step is added before the normal frying system. Read more about Rosenqvists coated French Fry system here!

STEP 7: FREEZING & PACKING

After the de-fatting step the golden French fries will enter the freezer on their way to the packaging system. The line can also be equipped with a pre- cooler installed before the freezer.

SEASONING

We are offering four different standard configurations of our seasoning system. All four configurations can be designed and customized for any coating need. Slow speed, gentle action, and uniform product depth prevent product brea-age and ensures optimal coverage for consistency with all types of seasoning. All seasoning systems are built on one skid for ease of installation and the design has been optimized for easy access and cleaning.

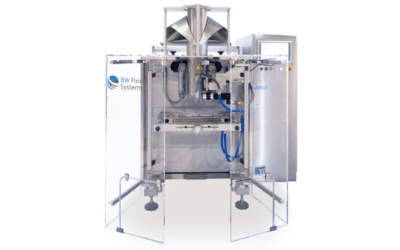

DISTRIBUTION

We are offering four different distribution machines, from a basic system with manual control to the most sophisticated solution including automatic mass flow of snack throughput. The solutions can be designed to your specific needs.